The Custom Solutions

The pinnacle of customization for every need

The study that led Restart to develop the Standard Module has also prompted the company to explore different solutions, with a higher level of prototyping. The Restart module, in fact, while allowing customization of processes and dimensions, retains a highly modular base from a mechanical and electronic perspective, which is not always compatible with the identified needs.

This is why Custom Solutions are born: a series of variants complementary to the standard Module, which integrate with it on automatic and semi-automatic lines signed by Restart.

Each of these solutions can be integrated with optional features that enhance performance in terms of safety, productive performance, but also design and operator comfort. Among these optional features, we find: preparation of FEM and air connections on the roof, safety PLC, 60 customizable light tower options, pivotable FootMaster wheels with buffers, Android application for just-in-time process data, among others. Even the painting can be customized upon customer request.

Manual Module – with dimensions of 1500x900x2200, the Manual Module features a large work area for the operator. Guided by the HMI (23-inch LED display with ultra-sensitive touchscreen) positioned in front of them, the operator performs manual operations on the pallet, such as loading and unloading components. The Manual Module accommodates Bosch or Montratec line segments on which pallets of different sizes move: 240×240, 320×320, 480×480. In addition to the already mentioned optional features, the basic version can be integrated with some extras designed to improve performance and operator comfort. Among these are: sensor for automatic adjustment of light intensity in the module, a true operator comfort zone (targeted conditioning, smartphone support with charging area, etc.), or a pick-to-light system for guided component loading.

Re-work Module – with dimensions of 1500X900X2250, the Re-work Module is also designed for interaction with the operator, who, guided by the HMI (23-inch LED display with ultra-sensitive touchscreen), proceeds with the disassembly of components. This Module is intended for disassembling pre-assembled components. The discarded components automatically enter the Module, which reads the type of waste from the pallet. The operator proceeds with disassembly, and the system objectifies the operation, through sensors placed on the ducts where the disassembled components pass. Segregated bins located below the objectification ducts collect the components. The operator can then reintroduce the pallet into the line where assembly will resume from the station that generated the waste. This module also accommodates Bosch or Montratec line segments on which pallets of different sizes move: 240×240, 320×320, 480×480. The Re-work Module can be integrated with optional features that improve the quality of the operator’s work, such as: sensor for automatic adjustment of light intensity in the module, operator comfort zone (targeted conditioning, smartphone support with charging area, etc.), pick-to-light system for guided component loading.

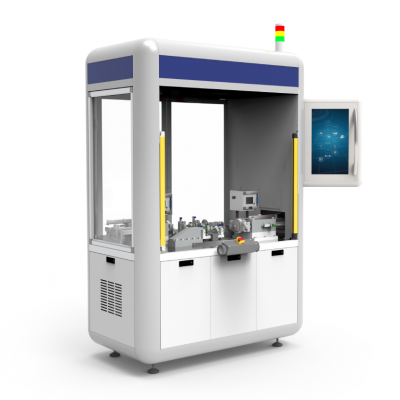

Semi-automatic Module (operator area 900) – unlike the other modules just described, this is a semi-automatic module. This module is designed to perform automatic assembly and testing operations, with manual loading and unloading of components. The operator is guided by the HMI (23-inch LED display with ultra-sensitive touchscreen) positioned in a column to the right of the module, and custom assembly and testing equipment perform automatic operations. The Semi-automatic Module (operator area 900) can also be integrated with optional features that improve the quality of the operator’s work, such as: sensor for automatic adjustment of light intensity in the module, operator comfort zone (targeted conditioning, smartphone support with charging area, etc.), pick-to-light system for guided component loading.

Semi-automatic Module (operator area 1400) – this module differs from the one just described mainly for the available work area for the operator. In this case, the 23-inch LED display with ultra-sensitive touchscreen is installed on an external rotating structure, allowing the entire bench area to be used for operations. With dimensions of 1500x1000X2250, this Module was born from the need of a well-known customer in the automotive sector, who needed to group various assembly and testing operations into a single structure. The Semi-automatic Module (operator area 1400) can be integrated with all the aforementioned optional features.

Double-station Semi-automatic Module – with dimensions of 1910x1080X2250, this solution is characterized by a double manual loading and unloading station, through which operators interact with automatic assembly and testing operations. In operations, operators are guided by the HMI (23-inch LED display with ultra-sensitive touchscreen) positioned in the center of the Module and clearly visible to both. All the aforementioned optional features can also be integrated into this type of Module.

Restart Totem – designed to accommodate the supervision PC of production lines, the standalone Totem Restart has two main features. The first is the housing for display and PC. The PC is positioned on the back of the Totem at the bottom. The paneling covers the connection cables with the 23-inch LED display, preserving easy access to the device. The second feature concerns the support for keyboard and mouse. The Totem has a front mini-desk easily adjustable in height, designed to adapt to the needs of different operators. With dimensions of 595x1970x1020 (plan depth), the design of the Totem is studied to integrate perfectly with Restart Line Modules. The rounded ends ensure ergonomics, a valuable added value for an object that fits into environments populated by operators. The painting can be customized upon customer request.

These are the main Custom Solutions offered by Restart, but it doesn’t end here. The continuous change of customer needs and the exploration of always new sectors push us to study innovative solutions every day. Something important is already in the pipeline. Follow us to stay updated on all the news and visit the pages of our Custom Solutions.